Image Credit: R_Boe/Shutterstock.com

Industrial automation is the application of automatic control to large scale processes and systems (sets of processes) such as factories, telephone switchboards, ships, and stock exchanges. Industrial automation is where machines are created and employed to automatically control parts of industries cheaper, more efficiently, and safer than humans could.

This interdisciplinary area applies innovations in materials science, computing and information science, robotics, engineering, project management, and systems designed to continually drive industry’s adoption of faster, more energy and cost-efficient, and accurate automated processes.

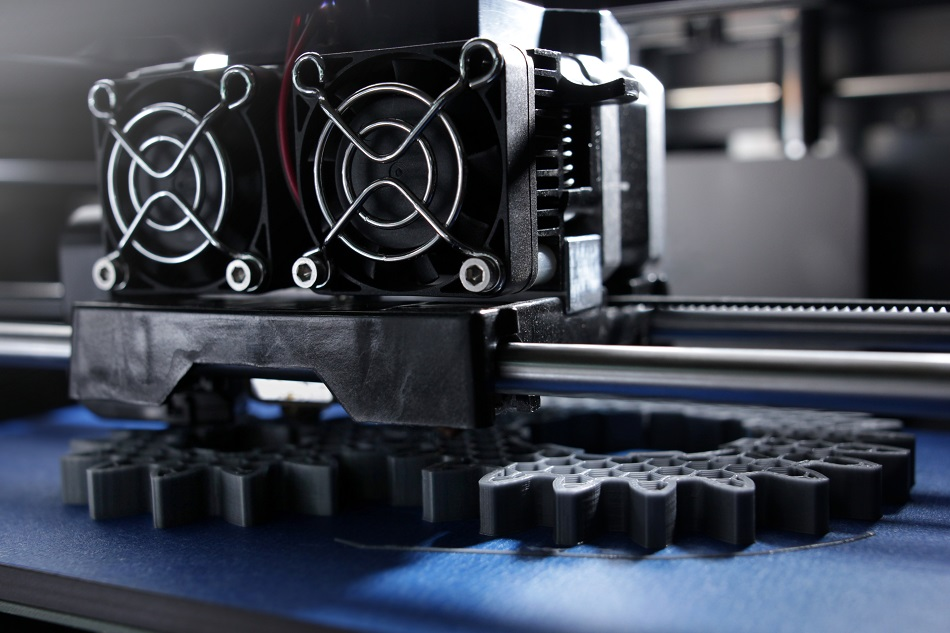

All of these fields can benefit from rapid prototyping. Rapid prototyping is a relatively new method in research and development enabled by the development of three-dimensional computer-assisted design (CAD) programs and advances in 3D printing. With these tools, designers and engineers can quickly generate workable prototypes of new components and systems, evaluate their strengths and weaknesses, and reiterate the design process.

This ability to cycle through multiple design iterations relatively cheaply benefits industrial automation by enabling new automatic systems to be perfected component by component, and for the whole system to be modeled and tested for inefficiencies. Below are a few examples of rapid prototyping benefitting industrial automation.

Component Repair and Refurbishing

With CAD models of entire industrial automation systems (such as an automobile factory), including each component, repairs for system failures as well as routine maintenance can be done much more efficiently and accurately.

Rapid prototyping enables engineers to test new materials or components that can bolster the existing system, or replace a part that was performing poorly. They can quickly create models of the new piece and test them in a physical environment to ensure they will work with the automated process already in place.

Mechanical System Modelling and Testing

Rapid prototyping also enables industrial automation engineers to design entirely new automated systems and individual processes within those systems.

It makes the design process far less time-consuming and wasteful, as discrete parts can be tested and perfected while a computer model of all of the parts working together can be used to spot mechanical failures.

Rapid prototyping also ensures the most efficient systems possible. Engineers can test models to ensure time and energy is not wasted in the automated process, without having to construct it in its entirety.

Software Engineering

Rapid prototyping does not only refer to designing and 3D printing physical parts and objects. Software engineers use rapid prototyping methods such as user testing and continual design reiterations to ensure no bugs or defects are within the final code.

In industrial automation, designing software that is both user-friendly and which controls the automated processes effectively is a challenge. Rapid prototyping can benefit this area of industrial automation by ensuring only robustly designed and tested software is controlling the automation.

Machine Learning

Industrial automation will benefit greatly from rapid prototyping as it is applied to the information science pursuit of artificial intelligence (AI). The combination of rapid prototyping methods using design software and 3D printing with intelligent software (which can learn from its own experience) enables the automation of the design process. This is called machine learning.

The process of machine learning involves a piece of software programmed to design objects according to set parameters. These objects can be automatically 3D printed, and then inspected automatically using various sensors and tests which are pre-set.

The information from this testing is then gathered by the machine learning software and used to reiterate the design of the object with fewer failures or inefficiencies. With enough computing power, well-designed algorithms for the software and appropriate materials all in place, machine learning could use rapid prototyping to benefit industrial automation by devising entire systems that are currently unimaginable.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.