Researchers at the Sandia National Laboratories researchers are developing methods to increase the application of prosthetics with flexible nerve-to-nerve or nerve-to-muscle interfaces integrated with electronics for treating amputees.

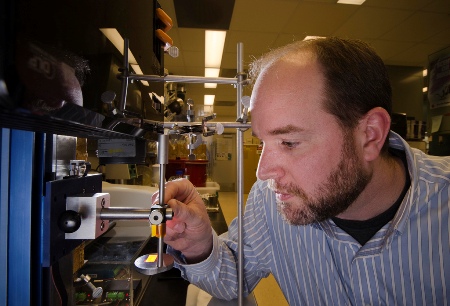

Organic materials chemist Shawn Dirk focuses a projector during work on neural interfaces, which are aimed at improving amputees’ control over prosthetics with direct help from their own nervous systems.

Organic materials chemist Shawn Dirk focuses a projector during work on neural interfaces, which are aimed at improving amputees’ control over prosthetics with direct help from their own nervous systems.

Robotics engineer Steve Buerger, organic materials chemist Shawn Dirk, and other researchers are constructing biocompatible interface scaffolds. They focus on an improved prosthetics method where the transected nerve fibers when connected to an electrode, is capable of generation. Neural interfaces can monitor nerve signals enabling amputees to control prosthetic devices.

Using patterned multiwalled carbon nanotubes or thin evaporated metal, flexible conducting electrode materials capable of complying with nerve fibers will integrate with nerve bundles. The interfaces need to be biocompatible to integrate with tissue and promote nerve fiber growth, mechanically compatible without impacting the nervous system or surrounding tissues, and provided with supreme conductivity with electrical properties optimized to transmit neural signals.

Based on the electrospinning technique, the team electrospun the scaffolds with two types of material such as PBF, or poly(butylene fumarate), a polymer fabricated at Sandia and UNM for tissue engineering, and PDMS, or poly(dimethylsiloxane) that will benefit the amputees, wounded warriors, and victims of peripheral nerve injury. This scaffold technique is expected to be patented. Following the development of interface materials, the surgeons at MD Anderson fastened the scaffolds into legs of rats in between the transected peroneal nerve, in order to evaluate the interfaces. Scaffold technique with PDMS seems to be more effective.

The team at the University of Illinois Urbana-Champaign developed a technique called microstereolithography, where a computer is coupled with a PowerPoint image connected to a projector whose lens is focused on a mirror that reflects into a beaker with a solution to fabricate a series of holes.