A scientist from the University of Texas at Arlington is guiding a project to bring automation to smaller composite manufacturing for urban air mobility (UAMs) vehicles and unmanned aerial vehicles (UAVs).

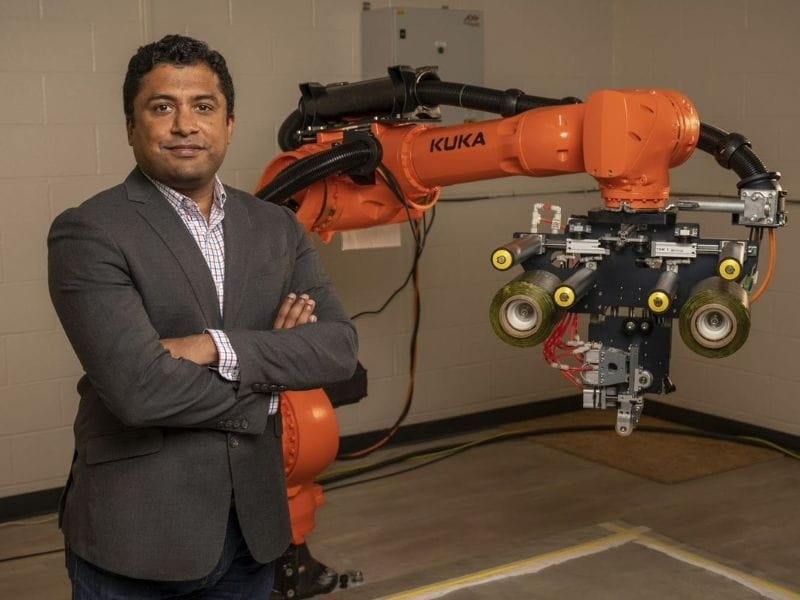

Paul Davidson. Image Credit: University of Texas at Arlington

Paul Davidson, a UT Arlington assistant professor in the Department of Mechanical and Aerospace Engineering (MAE), is heading the $249,770 Air Force Research Laboratory-funded project.

In the future, UAVs and UAMs will become ubiquitous, which means we will need to make high-performance composite material structures at a fraction of the cost and time. We are developing new manufacturing processes that combine state-of-the-art automated composite manufacturing and traditional molding to increase production output and improve structural performance.

Paul Davidson, Assistant Professor, Department of Mechanical and Aerospace Engineering, University of Texas at Arlington

Davidson stated that the majority of the composite manufacturing utilized for bigger aircraft is executed with automated robotic manufacturing. However, similar automation is hard on smaller UAM or UAV vehicles due to their high curvatures and complicated shapes.

Almost half of bigger modern commercial aircraft have been composed of composite materials. For UAVs, this number goes up to about 90%, stated Davidson.

When the UAVs and UAMs get smaller and with high curvatures, the composites face several challenges like shearing and wrinkling, which lead to poor structural performance and overdesign. On a larger scale, we can have robots do the work. We need to bring that to a smaller scale.

Paul Davidson, Assistant Professor, Department of Mechanical and Aerospace Engineering, University of Texas at Arlington

He said the US Air Force must have reliability in the field.

Davidson stated, “These units aren’t inexpensive. The guidelines are, therefore, stricter. They can’t fail on the battlefield. We must ensure combat readiness for the Air Force.”

MAE Chair Erian Armanios said Davidson’s work can convert smaller aircraft composite manufacturing.

Armanios Stated, “It’s a gamechanger in manufacturing. It’s an exciting project because of the growth of UAVs and UAMs and their broad applications.”

The new manufacturing method will be developed in UTA’s Laboratory for Advanced Materials, Manufacturing, and Analysis. The laboratory has come up with a special Automated Fiber Placement system for research performed on advanced composite manufacturing.

The manufacturing research cell provides UTA with a state-of-the-art system to investigate and develop new technologies. It also allows our students to learn advanced manufacturing, which is crucial for future workforce development.

Paul Davidson, Assistant Professor, Department of Mechanical and Aerospace Engineering, University of Texas at Arlington